Gain job-ready skills in cutting-edge computerized manufacturing methods and computer-aided drafting techniques.

What is Computerized Manufacturing and Machining?

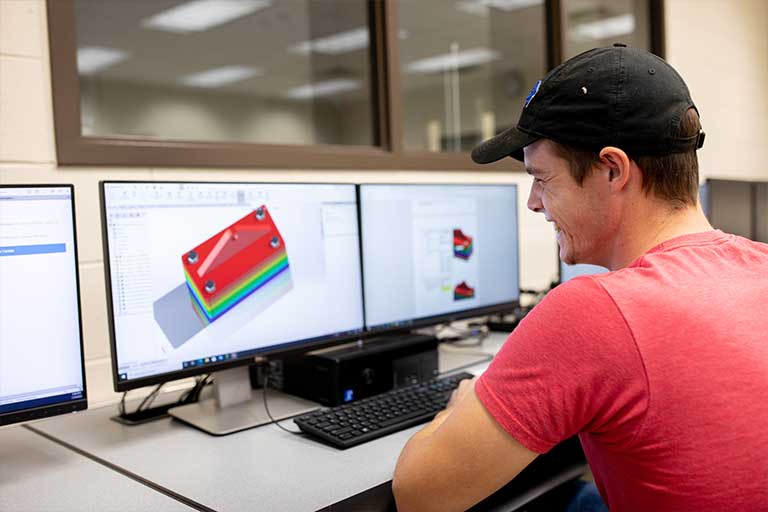

The Computerized Manufacturing & Machining program is a sequence of courses that prepares students for their future careers. This program provides learning opportunities to develop academic, technical, and professional knowledge and skills required for job acquisition, retention, and advancement. The program emphasizes a combination of machine tool theory and practical application necessary for successful employment. Our up-to-date laboratory facility and equipment, and our well prepared faculty are just some of the reasons why Somerset Community College has remained a strong force for serious technical preparation in the machining trades.

Getting Started

What are my degree, diploma, and certificate options?

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| MAT 116 - Technical Mathematics or Transitional Math | 3 |

| Transitional Reading or Computer Literacy | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 124 - Applied Machining | 6 |

| CMM 132 - CAD/CAM/CNC | 3 |

| BRX 112 - Blueprint Reading For Machinist | 4 |

| Transitional Class or General Education from Area 1 (Writing/Accessing Information, Oral Communication, Humanities, or Heritage) | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 118 - Metrology | 2 |

| CMM 220 - Advanced Industrial Machining 1 | 4 |

| CMM 222 - Advanced Industrial Machining 2 | 2 |

| Transitional/Gen Ed if needed | (3) |

| Total | 8 |

| Class | Credit Hours |

|---|---|

| CMM 214 - Industrial Machining | 6 |

| CMM 298 - Practicum or CMM 299 - Cooperative Education Program | 1 |

| Transitional/Gen Ed if needed | 3 |

| Total | 7 |

Total credits for program: 47-59

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| MAT 116 - Technical Mathematics or Transitional Math | 3 |

| Transitional Reading or Computer Literacy | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 124 - Applied Machining | 6 |

| CMM 132 - CAD/CAM/CNC | 3 |

| BRX 112 - Blueprint Reading For Machinist | 4 |

| Transitional Class or General Education from Area 1 (Writing/Accessing Information, Oral Communication, Humanities, or Heritage) | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 118 - Metrology | 2 |

| CMM 220 - Advanced Industrial Machining 1 | 4 |

| CMM 222 - Advanced Industrial Machining 2 | 2 |

| CMM 230 - Conversational Programming | 6 |

| Transitional/Gen Ed if needed | (3) |

| Total | 14 |

| Class | Credit Hours |

|---|---|

| CMM 214 - Industrial Machining | 6 |

| CMM 240 - Introduction to 3-D programming | 6 |

| CMM 298 - Practicum or CMM 299 - Cooperative Education Program | 1 |

| Transitional/Gen Ed if needed | (3) |

| Total | 13 |

Total credits for program: 59

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| Transitional Math | (3) |

| Transitional Reading | (3) |

| Total | 10-16 |

| Class | Credit Hours |

|---|---|

| CMM 132 - CAD/CAM/CNC | 3 |

| Transitional Classes | (3) |

| Total | 3-6 |

Total credits for program: 13-22

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| MAT 116 - Technical Mathematics OR Transitional Math | 3 |

| Transitional Reading | (3) |

| Total | 13-16 |

| Class | Credit Horus |

|---|---|

| CMM 132 - CAD/CAM/CNC | 3 |

| BRX 112 - Blueprint Reading For Machinist | 4 |

| Transitional Classes (if needed) | |

| Total | 7 |

Total credits for program 20-23

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| MAT 116 - Technical Mathematics OR Transitional Math | 3 |

| Transitional Reading or Computer Literacy | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 132 - CAD/CAM/CNC | 3 |

| BRX 112 - Blueprint Reading For Machinist | 4 |

| Transitional Classes | |

| Total | 7 |

| Class | Credit Hours |

|---|---|

| CMM 118 - Metrology | 2 |

| CMM 230 - Conversational Programming | 6 |

| Transitional Classes | |

| Total | 8 |

Total credits for program: 31

| Class | Credit Hours |

|---|---|

| CMM 114 - Fundamentals of Machine Tools | 7 |

| CMM 130 - Manual Programming | 3 |

| MAT 116 - Technical Mathematics OR Transitional Math | 3 |

| Transitional Reading or Computer Literacy | 3 |

| Total | 16 |

| Class | Credit Hours |

|---|---|

| CMM 124 -Applied Machining | 6 |

| CMM 132 - CAD/CAM/CNC | 3 |

| BRX 112 - Blueprint Reading For Machinist | 4 |

| Transitional Classes | |

| Total | 13 |

| Class | Credit Hours |

|---|---|

| CMM 118 - Metrology | 2 |

| Transitional/ Gen Ed if needed | (3) |

| Total | 2-5 |

Total credits for program: 31-35

How Do I Pay For This?

What Else Do I Need to Know?

Additional Information

To increase student success, our program has chosen to stress the learning of functional tasks rather than to promote an environment where students choose their own projects. All of our laboratory exercises are designed to introduce students to a broad scope of tasks typically performed on conventional or CNC machines. Our technical advisory group annually reviews our curriculum. They guide our decisions to include new topics, delete out-of-date ones, and to continue those that are still viable.

Our conventional machining program stresses the set up and operation of lathes and vertical mills for a wide variety of processes. The classes provide instruction in blueprint reading, shop math, measurement and inspection, job planning, safety, and general machining theory. Our CNC program also emphasizes the set up, operation, and programming of vertical mills and lathes; to include aspects of wire and sinker EDM.

In manual programming courses, students learn proper formatting of CNC code, calculations related to determining coordinate data, proper use of programming techniques such as the use of sub programming, and experience cutting parts using their own programs on our CNC machines. In computer assisted programming classes students learn how to use software such as Mastercam to generate machine code for CNC mills and lathes. All classes are structured with time allocated for lecture/demonstrations and hands-on laboratory time.

Length of Program

You can earn an associate in applied science degree in two years if you maintain full-time status.

This information should not be considered a substitute for the KCTCS Catalog. You should always choose classes in cooperation with your faculty advisor to ensure that you meet all degree requirements.