Pioneering change: SCC leads in innovative technology that will help “rebuild” America

Published on Nov 25, 2024

Somerset Community College (SCC) is making history as the first institution in Kentucky

to embrace innovative additive manufacturing commonly known as 3D printing technology.

This pioneering initiative aims to speed up the use of this technology within the

construction industry. The goal is to provide affordable and resilient housing solutions

that could be essential for surviving and rebuilding after natural disasters.

Somerset Community College (SCC) is making history as the first institution in Kentucky

to embrace innovative additive manufacturing commonly known as 3D printing technology.

This pioneering initiative aims to speed up the use of this technology within the

construction industry. The goal is to provide affordable and resilient housing solutions

that could be essential for surviving and rebuilding after natural disasters.

In recent years, Kentucky and the Appalachian regions have faced devastating losses from tornadoes, floods, and even hurricanes. Natural disasters that seem to now regularly exceed predictive weather models. In response to these challenges, SCC’s adoption of additive manufacturing, serves as a beacon of hope for many homeowners.

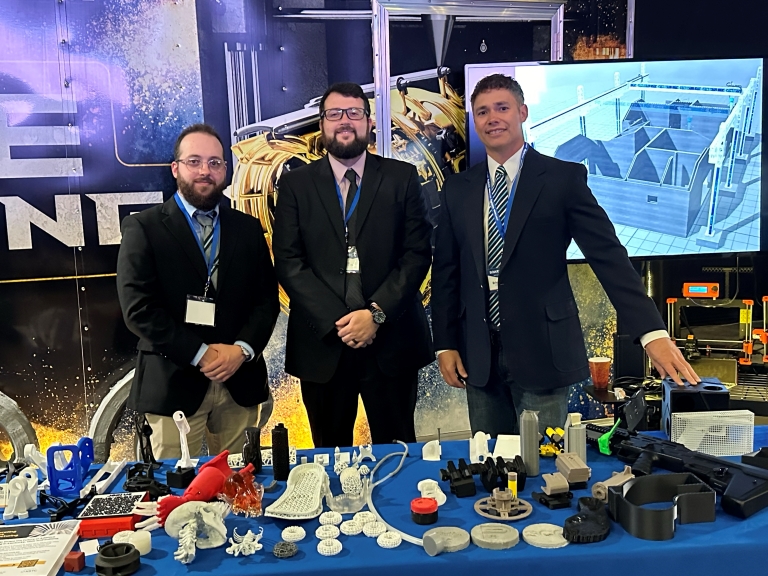

“Over a decade ago, Eric Wooldridge, Director of KCTCS Additive Manufacturing Center at SCC, seeing what was about to happen with the technology, began the movement to bring additive manufacturing skills and education to Kentucky at large,” noted Andrew Clapper C3DP Project Manager, a member of the SCC team. “SCC was the first institution in the nation to develop a statewide additive manufacturing certificate program.”

Wooldridge and his team are now aiming to expand their efforts in additive manufacturing on a grander scale. “Over the past decade, we’ve learned a great deal of valuable lessons,” Wooldridge remarked. “Because of our amazing partnerships with the Kentucky Science & Technology Corporation, University of Kentucky, University of Louisville, our sister KCTCS colleges along with direct support from the National Science Foundation and the USDA Rural Development, we were able to become the pathfinders in how to democratize and rapidly scale 3D printing education across an entire state. Now it is time to do the same with concrete 3D printing.”

Their vision is clear: to employ additive manufacturing technology to construct resilient homes capable of withstanding future floods and tornadoes.

“Additive manufactured structures are exceptionally durable. The cost and timeline to build with this technology compared to conventional methods are markedly different,” Clapper explained. “I truly believe this technology embodies the future of home building.”

Mark Mason, USDA RBCS Specialist, commented on the importance of this new technology for Kentucky.

“Advanced Manufacturing has proven to change the dynamics in modern business production, touching nearly every industry. It is exciting to see the possibilities it can bring to the current challenges of housing shortages and affordability in rural areas, along with the opportunities to create new, high-paying jobs.”

Wooldridge emphasized the importance of rebuilding with resilience in mind. “If we are going to rebuild, why not utilize technologies and materials that can endure floods and mitigate concerns often associated with mold and contamination? Why not move toward building structures that can make us feel safe and can last well over a century?”

SCC’s foray into this innovative technology has garnered funding from the USDA and the Appalachian Regional Commission (ARC). While experts at SCC acknowledge that fully integrating this technology into existing residential building codes and standards will take time, it is already being successfully implemented in other states and countries.

“Our project aims to demonstrate how building code requirements can be met with additive manufacturing technology used for structures, ensuring they meet all permitting standards,” Wooldridge stated. “We also want to demonstrate to contractors and developers how this technology paired with cutting edge engineering applications can effectively to produce affordable, next generation homes that meet federal financing qualifications.”

The Additive Manufacturing team at SCC is dedicated to staying at the forefront of the industry and is making strides to equip students with this cutting-edge technology across Kentucky. Pointing out that the power of additive manufacturing has less to do with the technology itself and much more to do with the mentality it takes to truly harness it.

Located in the Southeastern Appalachian region of Kentucky, SCC is doing just that.

“Students and workforce partners of SCC and eventually all of KCTCS, will have an advantage over the rest of the nation. Our team is extremely unique in its years of architectural, engineering, construction, and additive manufacturing expertise. And we are laser focused on using that expertise to develop engineering, design, and practical application trainings specifically for students and the workforce.” Clapper said. “Our students and trainees will be the first to take on this new knowledge at scale and use it in the most practical ways possible.”

Wooldridge continued, “Additive manufacturing, whether big or small and using plastics, metals or concrete is the application of choice for people that want to get things done. A technology that vastly reduces the barriers for people to try new things and to push the envelope,” Wooldridge stated. “Our mission here at SCC, as it always has been, is to pave the way for people to replicate and scale what we are doing. To find ways to put this technology in every school and community and give them the power to innovate. Because that is not only what Kentucky needs, but also our nation and our world.”

Through its commitment to advancing additive manufacturing technology, Somerset Community College is not just going to build homes; it is building a resilient future for families and communities in Kentucky and beyond.